4.3-10 Connector: The first choice interface

Ever since its introduction in 2015, the 4.3-10 connector has grown out to be the standard interface in mobile communication networks taking over the place the 7-16 connector occupied for decades. What are the design features that make this connector such a good fit for the ever-increasing requirements of mobile networks? You will find out in this article.

Our partner Spinner was one of the main developers of the connector. If you would like to read the story behind the development of this connector, you can read it here.

The key to success from a design perspective is the separation of the electrical and mechanical plane which asks for a different approach to contacting the outer contact. Since there is a spring-loaded inner conductor there is no front force needed to maximize contact and there is a higher degree of certainty of a reliable connection. This is opposite from the method of traditional connectors like 7-16 and N.

Apart from a better connection method that ensures great electrical performance, the connector is also 33% smaller and even 60% lower in weight than the 7-16 connector. This allows for higher density equipment design supporting the roadmap towards smaller equipment. The 4.3-10 connector is also IP68-certified which makes it suitable for both indoor and outdoor use.

Find an overview of all the features and benefits below:

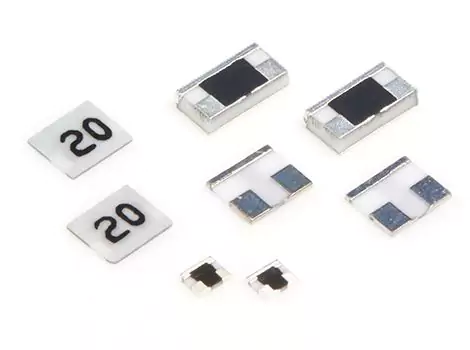

The 4.3-10 interface is based upon a universal socket/female connector. There are 3 types of plug/male connectors that connect to that, each with its own benefits.

Screw type connectors show highest mechanical stability and lowest PIM risk under dynamic conditions.They are insensitive against accidental opening by torque forces on the cable. This is our recommendation for outdoor base stations and harsh environments like vibrations, wind load, possible icing.

Hand screw type are also designed to allow rotation of the cable. However, a hand screw coupling mechanism can be opened by applying a pulling and/or bending force together with a torque force. We suggest this connector is only used in stable indoor environments.

Push-Pull type connectors allow a free rotation of the cable and are therefore immune against any undesired opening by torque forces, even in combination with bending and/or pulling forces. It is a great option for applications where fast (un)mating is required.

If you would like to know more about this connector, do not hesitate to reach out to one of our product specialists.