EDLC and LIC versus Battery

Introduction

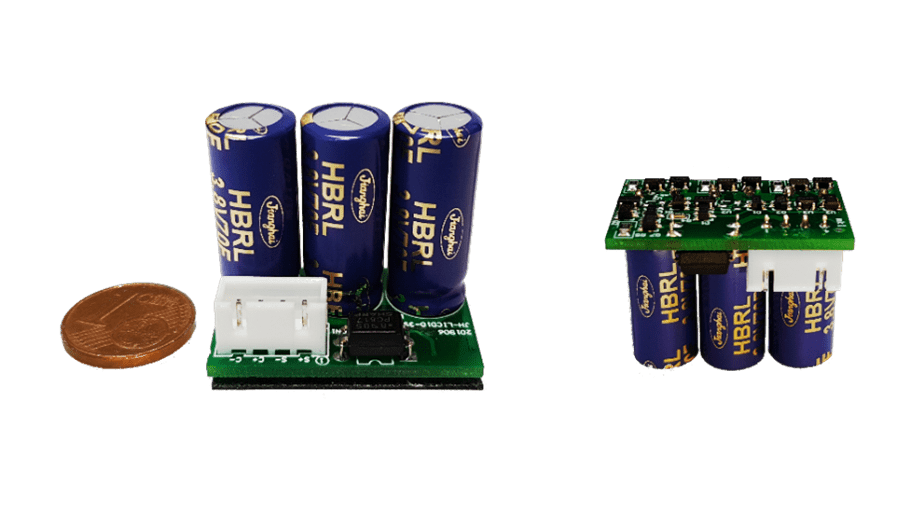

The worldwide need of batteries used in electric vehicles, electronics and as a backup for windmills is growing rapidly. The need for sustainability, clean energy and energy efficiency are driving this growth. A good way to store energy is key in a lot of ongoing developments. In parallel to the development in the Lithium batteries Jianghai, is constantly improving their Electric Double Layer Capacitors (EDLC) and the Lithium Ion Capacitors (LIC) which are called Energy-C within Jianghai. Especially used for short charge time and for regenerating and recuperation where you need high charge and discharge currents. From small handheld applications in our everyday life to large scale power plant technologies: energy storage devices are needed. The question is how can these storage devices meet the versatile challenges and how sustainable are these?

Is Electric double-layer capacitors (EDLC) the solution?

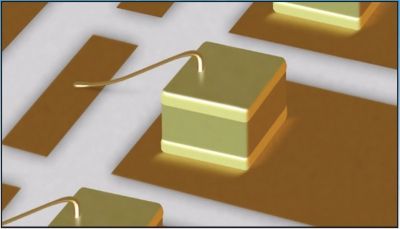

The basis of this capacitor are two activated carbon electrodes, which are applied to an collector foil. To prevent these two against short circuit a membrane is used (so-called separator). This separator is permeable for ions and serves as a reservoir for the liquid electrolyte.

When you apply voltage to the capacitor the ions are charged. They can flow in the liquid electrolyte through the membrane an go to the opposite charged electrodes. There they collect at the phase boundaries between the solid electrode and the liquid electrolyte and form the so called double-layer. The double-layer consists of ions from the electrolyte and de layer of counter ions in the electrode. An electric field is formed between the two charge carriers, which polarizes the molecular layer between them and isolates them from each other. It has a “charge-separating effect” and separates the two layers like the dielectric of a plate capacitor. This layer is also called “inner Helmholtz Layer”, together with the ion layer in the electrolyte (“outer Helmholtz layer”), it form the double-layer. This formation of the double-layer happens very fast because the ions are only absorbed and do not for a chemical bond. This results in a fast charge and discharge possibility of the EDLC. Be aware of specification which originate because of these layers the principle can only exist in a voltage range from 1.2V and 3.0V. If you cannot short circuit the capacitor it can lead to irreversible damage to the electrolyte.

Is a lithium ion capacitor (LIC) the solution?

This technology can be positioned between the EDLC and a battery, and combines the large power density of the EDLC and the high energy density of a battery. A lithium ion capacitor (LIC) is a capacitor that uses a carbon-based material capable of absorbing lithium ions as the negative electrode material, and it improves energy density by adding lithium ions to it. This creates the so called pseudo-capacitance electrode while using the principles of a general electric double layer capacitor on the other electrode.

The principle of charging and discharging differs between the positive electrode and the negative electrode, and the structure combines the negative electrode of a lithium-ion battery and the positive electrode of an electric double layer.

Here you see the difference in the electrode construction of the three technologies.

The doping of the ions at the negative electrode causes a voltage of at least 2.2V. If you have to charge the capacitor you need to apply a voltage higher than that. Together with the double-layer electrode it results in an output voltage up to 4V. Since the amount of energy stored in the capacitor increases quadratically with the voltage, the capacity of a 4V LIC is more than twice as high as that of an EDLC with 2.7V.

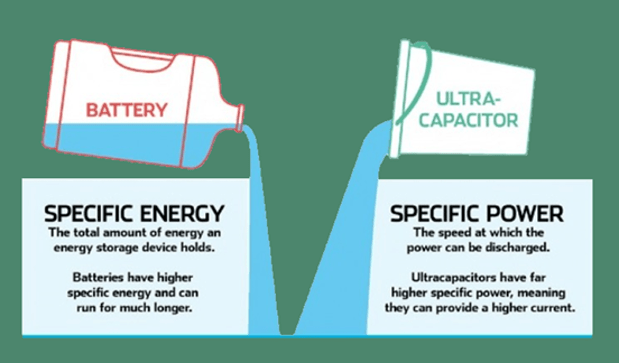

Energy-c or Battery

In the sheet below, you find an overview of the important specification of all three storage solutions. All of them have advantages and disadvantages. The energy-c part have much higher amount of charge and discharge cycles but a much lower energy density. You can use higher currents for charging and discharging which makes this ideal for quick charging and recovering energy. This situation has in contrast with batteries no effect on the lifetime. A battery can deliver power for a longer period and can hold more energy.

What to choose for your application?

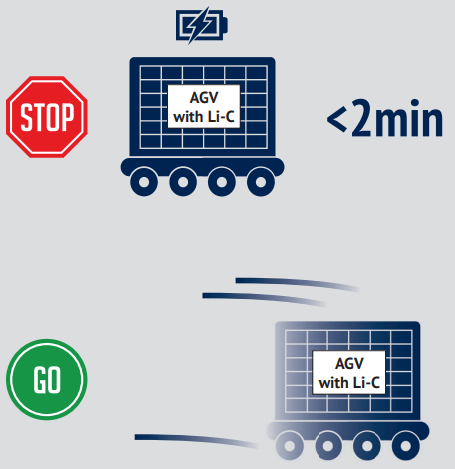

I think Energy-C is not a replacement for a battery in all applications. But in combination with batteries it can help to lower the self-warming of your battery pack, when you have a high inrush situation, a hybrid solution (Battery and Energy-C) can help to increase the life cycle of your battery. This inrush can also be seen in applications where you have data transmission to connect to any kind of wireless system. An application where Energy-C can replace batteries is maybe a Automated Guide Vehicle. The advantages there are less weight and volume, which means more load. Quick charge what can lead to an effective use of al vehicle (a battery charges AVG is standing still for approximately 4 hours when charging)

Future of Energy-C

A lot of engineering on the above energy storage component is going on. Jianghai is always working on this and the limits of this technology is not reached jet. The roadmaps below show you where Jianghai thinks they will be in a few year. And maybe Energy-C can be replacing batteries in the future.

Roadmap Jianghai LIC’s