Capacitor-driven electric bus

›› As an environmentally friendly alternative to classic combustion engines, electric and hybrid drives in buses represent today’s e-mobility solution. These systems rely on classic, electro chemical batteries as storage device for the electric drive energy.

Jianghai takes a new way

Depending on the battery technology used, other topics are added to the typical range question, such as the charging concept, the weight, the volume requirement and, in particular, safety. The last point is especially of great importance in the area of passenger transport. In contrast to a large number of manufacturers who rely solely on battery technologies, Jianghai is taking a new path: instead of ever larger batteries, Jianghai is proposing the use of complementary capacitor modules in buses.

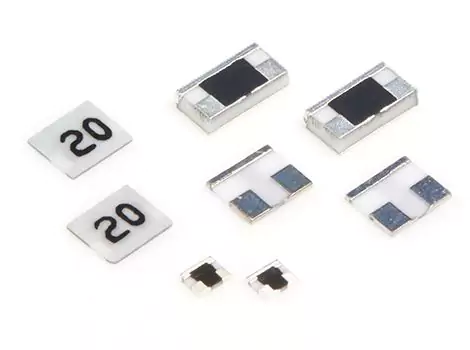

Different technologies are available depending on the application profile. They are summarized at Jianghai under the term „Energy-Cs“ and come from the family of double-layer capacitors („EDLCs“). For use in buses, the technology of Li-capacitors (abbreviated LiC) is of particular interest. They provide a link between batteries and capacitors, combining the best of both worlds.

Li capacitors offer the advantage of high power density and thus enable higher charging currents than battery modules. They allow this even with lower weight and volume. By avoiding chemical reactions, as is the case in battery systems, these capacitors are particularly cycle-resistant. Instead of only a few hundred to around a thousand possible charge and discharge cycles in an electrochemical battery, Li capacitors achieve many hundreds of thousands of cycles.

Highest security requirements

At the same time, they meet the highest safety requirements: Neither mechanical damage nor incorrect use lead to thermal runaway and thus to fire or explosion. In contrast, conventional battery modules require a great deal of effort in order to protect them in the best possible way against mechanical damage. The mechanical enclosure naturally reduces the energy density of the battery modules used.

Not to be neglected is the influence of the operating temperature on the function of a battery: High temperatures are disadvantageous for many battery technologies, yet also very low temperatures can have a harmful effect during operation. A lifetime reduction or even a complete failure are not uncommon here. LiCs do not have to struggle with this limitation, because they can be operated even at low temperatures without loss of service life or increased risk of failure.

Alternative charging concept

Despite all the advantages, LiCs are capacitors and thus a storage system with about five times lower energy density than that of a battery with the same weight (without taking into account the mechanical protection required for batteries). This is exactly where the Jianghai engineers start with the new bus concept: They did not try to install ever larger battery modules in order to achieve the longest possible range, but they rather changed the operating mode in order to be able to use capacitors instead of the batteries. Instead of a long term stop at a charging station for several hours, the buses charge their capacitor modules for a few minutes at each stop.

This mode of operation results in significant advantages

over the usual e-bus operation: the buses can run without interruption for charging in continuous 24/7 operation, since the charging process is completed in the minute range. Furthermore, there are weight and volume savings, which in turn enable a larger number of passengers. In addition, the energy storage system is no longer a source of danger in the event of an accident. A comparison between a regular, battery-powered E-bus and a LiC bus shows the main differences (see fig.).

Continuous further development

Jianghai is continuously developing LiC technology, appro aching the energy density of batteries without losing the technological advantages. Thus, the Li-capacitor technology should not only enable nationwide bus traffic in large cities, but also between more distant places.

More info about Jianghai Energy Capacitors you find here!