Irreplaceable modules

Efficient use of modern semiconductors in converters is almost impossible in a design with discrete components, as the distance between the components prevent the necessary low-inductance coupling and increase ohmic losses as well as parasitic side effects.

Film capacitor modules: minimizing inductivities and ohmic values

Capacitors are used in a wide variety of types in DC-link circuits of converters. In the interest of every increasing performance, driven by the desire for more efficiency and new semi-conductor technologies, DC-link voltages are rising to levels that cannot be reached by electrolytic capacitors. DC-Link capacitors with plastic films, covering the voltage range from 1000V to 2000V, offer a solution.

Due to the high voltages and the steep switching edges and frequencies that modern semiconductors cause in power applications, rather complex DC-link systems are usually necessary, consisting of:

- DC-link capacitors as storage elements

- Snubber capacitors to protect against voltage spikes

- Busbar constructions (often expensive and complex due to high current)

The construction in discrete structure results in high (parasitic) inductances and significant line losses due to the ohmic resistance of conducting tracks, soldered and screwed connections, that the excellent properties of modern semiconductors can only partially bring their power to the road. DC-link capacitor modules from Jianghai offer an elegant way to solve this issue.

Film capacitor modules: customized design, significantly easier assembly

In addition to the advantage of custom-specific design and thus perfect adaptation to the topology of the applications, developers can benefit from a significant simplification during assembly: the direct connection so semiconductors shortens the length of the current paths and thus minimizes parasitic inductance. Values in the singe-digit nH range are possible, so there is no need for additional snubber capacitors. Continuous currents of many hundreds of amperes can be achieved through cooling surfaces or coupling to water cooling systems. The typical voltage range is from 400V to 2500V.

Film capacitor modules: construction

Inside the module is a frame constructure in which several capacitor cells are usually connected in parallel.

Depending on the design, copper bars are inserted as additional current paths.

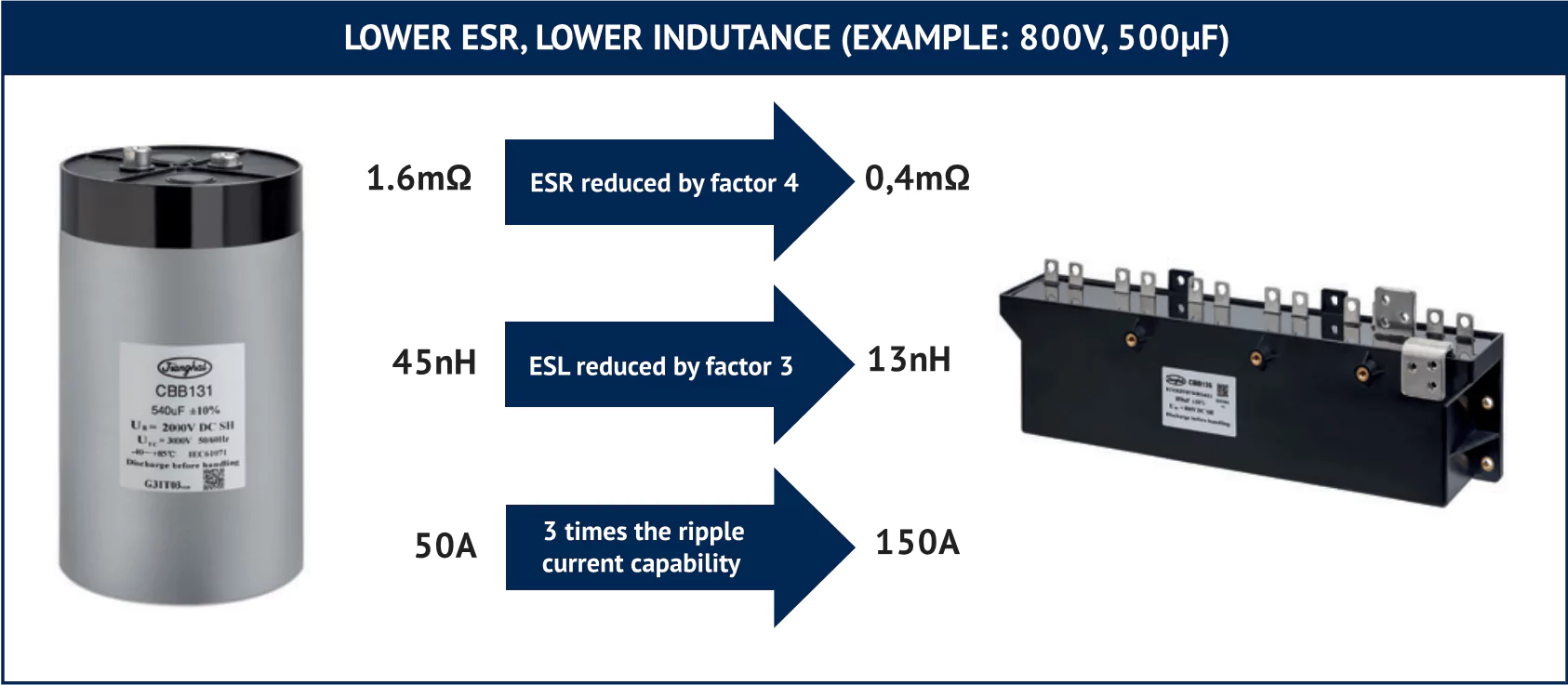

The comparison between a cylindrical film capacitor and a module highlights the advantages of the module technology:

While modules have previously been found primarily in automotive applications, e.g. in on-board chargers, they are now increasingly finding their way into industrial applications. Quantities starting from 100 pieces can be realized.

Summary

In order to be able to use modern semiconductors optimally in terms of efficiency and cost, the use of capacitor modules is very advantageous. Capacitor modules offer their users the design-options to realize the simplest and most powerful solution for their application.