Comparative Performance between Thick Film and Electron Beam Welded Metal Band Resistor Technologies

When designing a DC/DC convertor or battery management system, you typically use a low ohmic current sense resitor to measure the performance of your application.

HTR adapted a new technology that makes you able to create a reliable and precise current measurement at a smaller size and with lower power consumption.

Basic application

The Electron Beam welded and Thick Film current sense resistors are predominantly used in the DC/DC convertor output block and in battery management. The basic circuitry followed is that these low ohm resistors are connected in series with the load and the potential difference between both terminals are measured by an IC to determine the intensity of the current. The performance of IC’s available today has made great strides which enable them to measure current more accurately by being able to read ever diminishing potential differences. By using ultra low resistance values, it is possible to detect even large currents over 160 AMP, with lower power consumption as compared to devices being presently used.

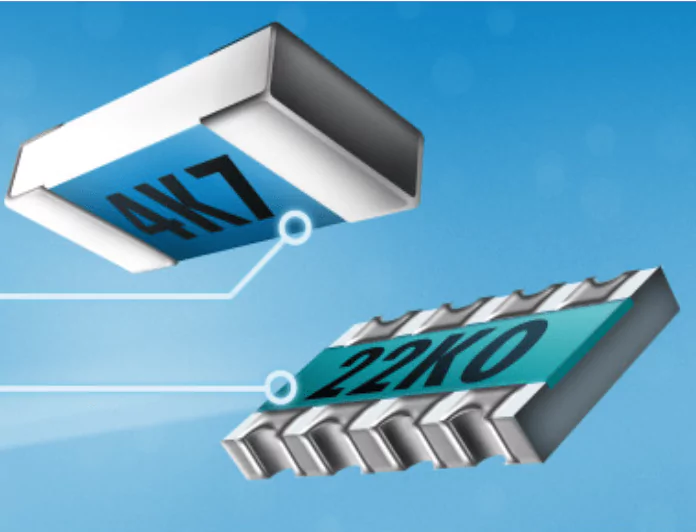

Construction of the resistors

Low ohm resistors using the older Thick Film technology are made by screen printing the resistive element and electrodes on an alumina substrate. The Thick Film resistors which are available today have, generally speaking, resistance range in tens of milliohms. The Electron Beam welded metal band resistors have a very rugged construction where the different resistance alloys selected are welded to the copper electrodes. The very nature of the construction of these resistors contribute to excellent heat dissipation as compared to the Thick Film variety.

Electron Beam vs. Thick Film

Using this technology it is possible to make components with a resistance range of several milliohms which mean a much lower resistance value as compared to Thick Film components. Besides with the characteristic of superior heat dissipation as compared to the Thick Film devices, it lends itself to providing a smaller & more reliable device. Hence, the metal strip resistors offer higher power and very precise temperature co-efficient of resistance as compared to Thick Film devices. Further since these Electron Beam welded metal band resistors can be made having resistance value much lower than Thick Film components, they have the added advantage over Thick Film components by being able to exploit the property of the latest IC’s which can now measure even the smaller potential differences. HTR, as being an ISO/TS 16949:2009 company, is committed to offering the customers a full range of resistive devices using the latest Electron Beam technology to contribute to the enhanced detection accuracy, reduction in the size of the devices and in conserving power consumption.

Main Advantages

- Precision and power resistors

- Precise measurement results

- Very precise temperature coefficient (TC)

- Low resistance value

- Low power consumption

- Small size